EPS/Foam CNC Router

Blue Elephant: Your Reliable CNC Foam Router Supplier

Reduce Costs 30%, Increase Profits 42%

with Our CNC Machine.

Connect With Us

For any inquiries, don’t hesitate to contact us at:

- [email protected]

- +86 186 6899 1371

Explore More via Video

Related Products

-

E200 Double Head Side Hole Drilling Machine

Read more -

Double Head Hinge Hole Drilling Machine

Read more -

ET6 6 Sided CNC Drilling Machine with a Return Table

Read more -

420 Computer Beam Saw Machine for Sale

Read more -

CNC-32TA Sliding Table Saw with Digital Control

Read more -

EM3.2-1126 Through-type Double-channel Door Lock Making Machine

Read more -

EM2.1-1128 CNC Through Type 4 Sides Wood Door Cutting Saw

Read more -

EK2-1328 Linear ATC CNC Machining Center

Read more

Customization Options

Specs & Functions

CNC machines tailored in size, power, and system to meet your needs

Aesthetic Design

Custom colors and styling to enhance your brand identity

Branding Service

OEM solutions with your logo for market distinction

What Sets Blue Elephant Ahead

Superior Quality

100% inspection and 160 checks ensure precision and zero issues.

Cost Effectiveness

Efficient manufacturing meets ISO9001, SGS, CE, BV standards at competitive prices.

Precision Custom

Advanced CNC technology with yearly upgrades keeps products at the cutting edge.

Innovation Focus

Advanced CNC and annual upgrades ensure innovation and top performance.

Reliable Support

A dedicated 50+ team provides 24/7 pre-sales, installation, and maintenance support.

Global Reach

A 75,000㎡ modern factory supports direct sales, regional optimization, and fast delivery.

Certified Excellence

International certifications and over 8,000 satisfied users build trust and credibility.

Extended Warranty

A 12-month warranty, along with a 60-day trial, ensures lasting peace of mind.

Real-World CNC Solutions

Discover how businesses across industries overcome production challenges with Blue Elephant CNC solutions. From improving precision to enhancing efficiency, our machines help companies achieve their manufacturing goals.

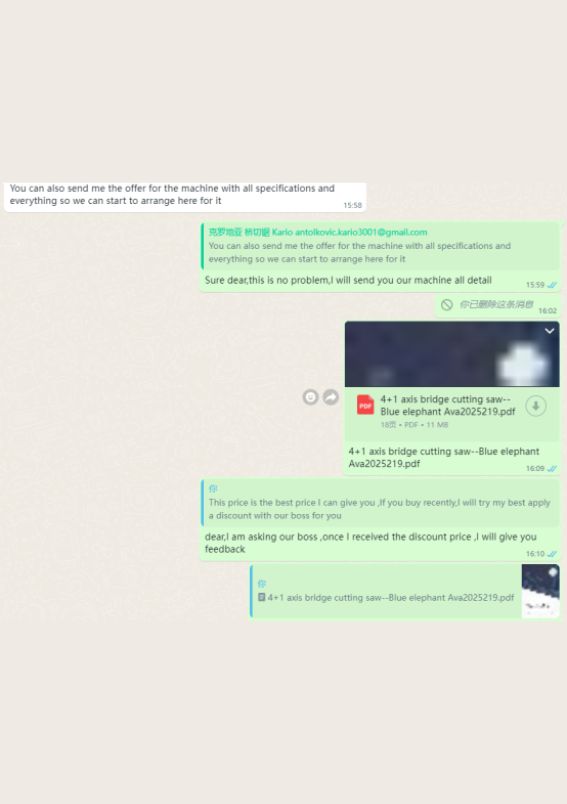

Croatia | Bathroom and Kitchen Furniture Manufacturing

Customer Challenges

- Expanding into kitchen and bathroom furniture

- Needs suitable CNC, considering bridge cutting saws

- Facing stock issues with local suppliers

- Price sensitive, comparing 4+1 and 5+1 Bridge Saws

- Seeks dependable suppliers for new operations

Our Solution

- Suggested the 4+1 Bridge Cutting Saw for its efficiency in bathroom and kitchen projects, suited to the budget.

- Detailed the benefits of 4+1 over 5+1 models, focusing on their cutting capabilities. Recommended 4+1 for its sufficiency.

- Explained galvanization of critical parts and use of antirust paint for others.

- Organized a visit for the customer’s agent to verify product quality and supplier reliability.

- Offered a timely discount to motivate quick decisions, emphasizing value and competitive pricing.

Final Results

- Customer chose the 4+1 Bridge Cutting Saw, suitable for their needs.

- Smooth process with clear communication.

- Customer confident in product quality and supplier partnership.

Ecuador | Personal Studio for 3D Model Creation

Customer Challenges

- Starting a new business in 3D model production

- Limited experience with CNC machines, worried about complexity

- Needs a budget-friendly, versatile, and easy-to-use solution

Our Solution

- Recommended the ELECNC-1530 ATC 4-Axis Router, featuring a spindle that swings ±90 degrees for complex tasks.

- Delivers ±0.03 mm precision, allowing high-quality 3D model creation.

- Confirmed the machine's user-friendliness, with ongoing free online support for a smooth transition to automated engraving.

- Discussed the growing 3D model industry, showing how this machine meets current and future needs, aiding market entry.

Final Results

- Shipped the ELECNC-1530 ATC 4-Axis Router to the customer’s studio in Ecuador.

- Provided comprehensive training and support, enhancing the customer’s confidence in using and maintaining the machine.

- Received positive feedback about the machine’s ease of use and precision, supporting future business expansion.

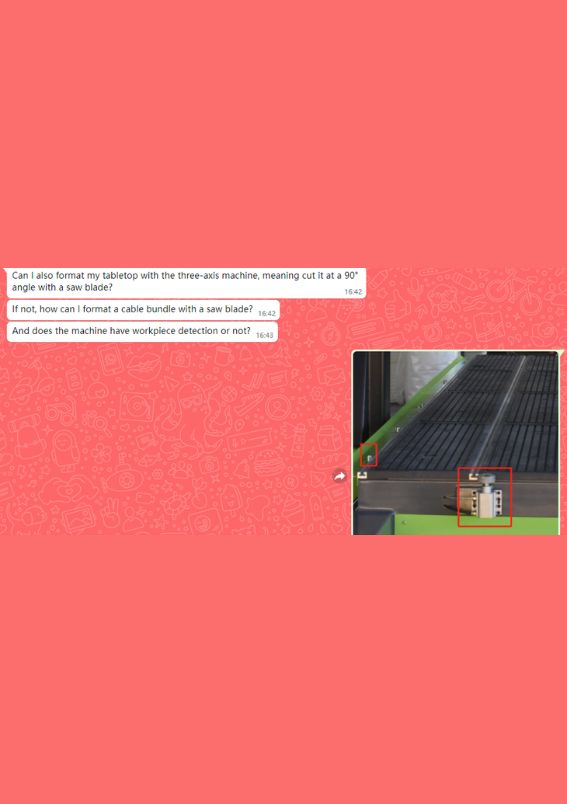

Austria | Wood Flooring Production

Customer Challenges

- Shifting from outsourcing to in-house wood flooring production

- Used a CNC machine with a right-angle head and saw blade, including an edge-seeking feature

- Uncertain about buying a similar machine or a cheaper option

- Budget capped at 15,000 USD for the initial machine purchase

Our Solution

- Recommended the standard ATC (Automatic Tool Changer) over the specialized right-angle head and saw blade, highlighting its efficiency for required tasks without the edge-seeking feature.

- Clarified cost benefits, showing the standard ATC fits the budget while meeting production needs.

- Compared both machine options, emphasizing functionality and clear differences.

- Kept communication clear and direct to aid the customer's decision-making.

Final Results

- Chose the standard ATC for its value and functionality.

- Installed successfully; performs well in production.

- Customer satisfied with guidance and support, considering a long-term partnership.

- Valued the budget-friendly, functional solution.

What Our Customers Say about Edge Banding Machine

SAUDI ARABIA

E-70JDSR Edge Banding Machine

After unloading the machines, the staff also placed, organized, adjusted and set them up diligently until we finally completed the work.

The quality of the finished products I saw was also very good and satisfactory. Hopefully this is a good start.

AMERICA

E-80 Edge Banding Machine

The customers purchased our CNC machine two years ago. This time, they came to purchase another edge banding machine.

" Actually we are using that machine for two years and we have a very good experience with it. They have very professional salesteam and customer service. Definitely we will be their customers again."

MAURITIUS

E-80L Edge Banding Machine

We are from Mauritius and we came here to look at some work machines. We got an edge banding machine and a beam saw.

And we see that the factory is really good. They have very nice production, great engineer. And overall so far we' re very happy with what we've seen. And we look forward to having the machines and starting to use them.

Montenegro

E-60 Edge Banding Machine

Our after-sales technicians went to Montenegro to debug the machine and provide guidance on machine operation.

The customer said the machine was very good and was grateful for our service.

About Our Factory

15+ years in business as an industry leader

75000+㎡ High-level Production Base

25+ Dedicated Production Bays

10 technical service centers around the world

30+ locations worldwide

500+ emplovees for service you

8000+ client' Trust and recognition

Exported to 180+ countries and regions

Our Valued Certifications

Blue Elephant CNC machines comply with internationally recognized standards, holding certifications such as CE, ISO9001, BV, SGS, and TUV. Our strict quality control processes and precision engineering ensure high-performance, durable, and reliable solutions that meet the demands of global industries.

Insights from Businesses Using Our CNC Foam Router

AUSTRALIAN

Impressed with Precision for 3D Foam Sculpting Projects

CNC Foam Router is the ideal machine for accurately cutting and shaping foam materials. Works great for EPS, XPS, PU, EVA, and similar soft materials. I use it mainly for 3D signage, event props, and architectural models.

SWISS

Fast Setup and Clean Cuts for Foam Packaging Inserts

CNC Foam Router makes packaging production super efficient. We use it to create protective foam inserts for electronics and tools. Smooth edges, precise dimensions, and easy operation make this machine a smart investment.

US

Excellent Machine for Custom Prop and Display Fabrication

CNC Foam Router has exceeded expectations. It cuts intricate shapes and textures for large props, displays, and exhibition pieces. It handles thick foam boards with ease and saves us hours of manual sculpting work.

25 Ways to Make Money with a CNC Foam Router

- 3D signage and channel letter production

- Custom cosplay props and costumes

- Architectural foam models and mockups

- Movie and stage prop fabrication

- Event decoration and large foam displays

- Themed party props and backdrops

- Prototype design for product development

- Automotive body kit prototyping

- Custom surfboard or board sport foam cores

- Lightweight exhibition stand elements

- Large-format sculptural art pieces

- Outdoor foam advertising structures

- EPS foam packaging prototypes

- Custom foam inserts for tools or cases

- Trade show display models

- Custom foam stamps for printing or crafts

- Themed photo booth props

- Foam lettering for interior décor

- Monument replicas and themed attractions

- Mascot or costume base sculpting

- Foam signage for weddings and parties

- On-demand CNC carving services for other makers

- Online sales of ready-to-paint foam decorations

- Foam model kits and DIY craft packages

- Mold making for casting and composites

Frequently Asked Questions

Connect With Us

For any inquiries, don’t hesitate to contact us at:

- [email protected]

- +86 186 6899 1371