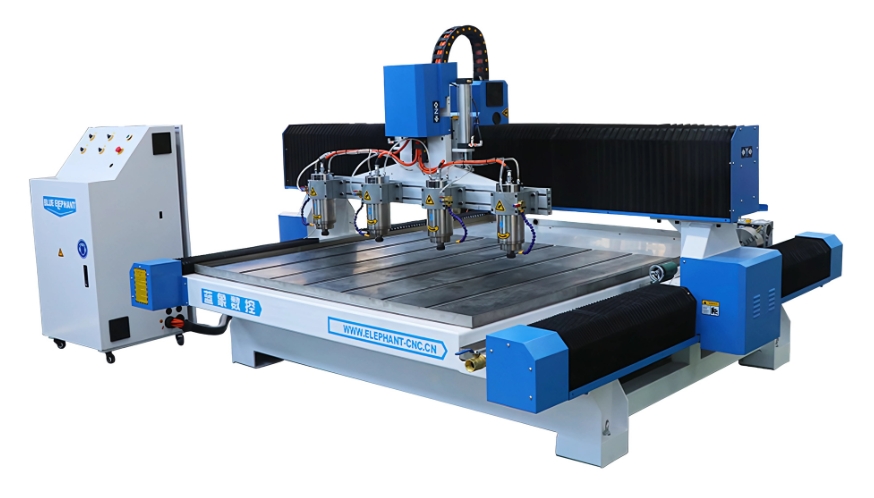

Stone CNC Machine

Blue Elephant: Your Reliable Stone CNC Machine Manufacturer

Blue Elephant stands out as a leading stone CNC machine factory, offering advanced solutions tailored for precision stone processing. Our machines are engineered for durability and stable performance, making them ideal for marble and other stone materials. With strong R&D capabilities and strict quality control, we ensure reliable machinery built to handle demanding workloads.

We also provide customized configurations to meet specific project needs. Backed by expert support and a commitment to innovation, Blue Elephant helps stone fabricators maximize productivity and achieve exceptional results in every application.

-

4+1 CNC Bridge Saw with Material Shifting Function

-

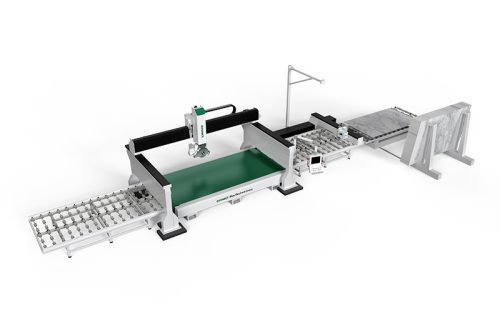

4 Axis CNC Bridge Saw Machine for Sale

-

4+1 CNC Bridge Saw Machine for Sale

-

5+1 CNC Bridge Saw with Blue Elephant System

-

5+1 CNC Bridge Saw with Italy ESA System

-

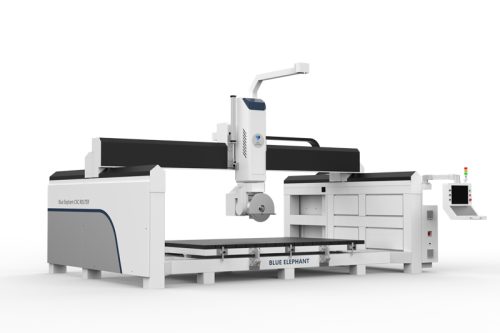

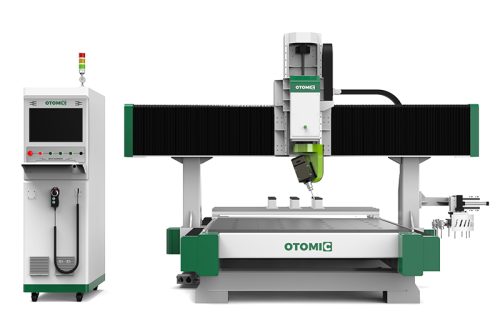

ES5 5 Axis CNC Stone Bridge Saw Machine

-

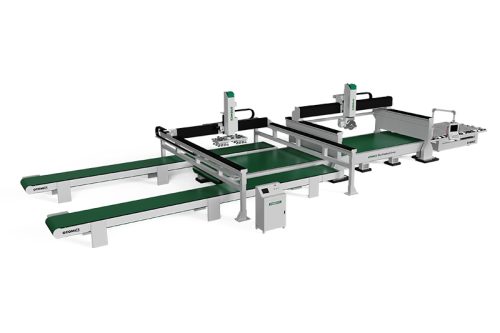

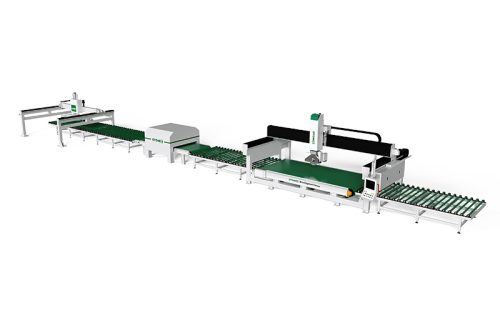

QX3400-5X-SP 5 Axis CNC Bridge Saw Quartz Slab Production Line

-

QX3400-5X-MP 5 Axis CNC Bridge Saw Granite Slab Cutting Line

-

QX3400-5X-LP 5 Axis CNC Bridge Saw Marble Cutting Line

Reduce Costs 30%, Increase Profits 42%

with Our CNC Machine.

Connect With Us

For any inquiries, don’t hesitate to contact us at:

- manager@elephant-cnc.com

- +86 186 6899 1371

Explore More via Video

Related Products

-

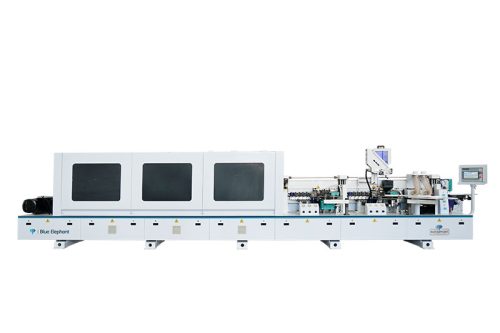

E-70JDSR Automatic Avoidance Edge Bander

Read more -

1325 4×8 ATC CNC Router with Laser Head

Read more -

1530E Fiber Laser Cutting Machine with Exchange Platform

Read more -

1825 ATC EPS Foam CNC Router for Sale

Read more -

380 Computer Beam Saw Machine for Sale

Read more -

EM2.1-1128 CNC Through Type 4 Sides Wood Door Cutting Saw

Read more -

EK2-1328 Linear ATC CNC Machining Center

Read more -

EW3 5 Axis CNC Router with Moving Column Gantry

Read more

Customization Options

We offer custom stone CNC machines designed around your specific requirements. From enhanced cutting power to unique dimensions and branded details, Blue Elephant ensures every machine fits perfectly into your workflow and business identity.

Specs & Functions

CNC machines tailored in size, power, and system to meet your needs

Aesthetic Design

Custom colors and styling to enhance your brand identity

Branding Service

OEM solutions with your logo for market distinction

What Sets Blue Elephant Ahead

Superior Quality

100% inspection and 160 checks ensure precision and zero issues.

Cost Effectiveness

Efficient manufacturing meets ISO9001, SGS, CE, BV standards at competitive prices.

Precision Custom

Advanced CNC technology with yearly upgrades keeps products at the cutting edge.

Innovation Focus

Advanced CNC and annual upgrades ensure innovation and top performance.

Reliable Support

A dedicated 50+ team provides 24/7 pre-sales, installation, and maintenance support.

Global Reach

A 75,000㎡ modern factory supports direct sales, regional optimization, and fast delivery.

Certified Excellence

International certifications and over 8,000 satisfied users build trust and credibility.

Extended Warranty

A 12-month warranty, along with a 60-day trial, ensures lasting peace of mind.

Real-World CNC Solutions

Discover how businesses across industries overcome production challenges with Blue Elephant CNC solutions. From improving precision to enhancing efficiency, our machines help companies achieve their manufacturing goals.

America

Tile and floor processing

The client is engaged in the construction industry and is ready to upgrade equipment to provide better cutting products.

Customer Challenges

- Needed better equipment for high-quality product cuts.

- Concerned about installation and training support in the U.S.

- Wanted reliable after-sales service and simple machine setup.

Our Solution

- Strong U.S. after-sales support with on-site engineer service.

- Showed evidence of frequent engineer visits to U.S. clients and positive review.

- Offered flexible online support for quick troubleshooting.

- 5-Axis Bridge Saw ships mostly assembled; only sheet metal needs setup.

- Shared past U.S. efficient delivery and setup examples.

- Shared U.S. client positive reviews on setup and use.

Final Results

- Smooth delivery and installation of the 5-Axis Bridge Saw.

- Engineer provided door-to-door setup and training; customer satisfied.

- Customer praised machine quality and support; deal successful.

America

Kitchen Countertop and Wall Processing

The client has just switched to kitchen countertop and wall processing.

Customer Challenges

- Switching to kitchen countertop and wall processing and have no experience.

- Unsure about the necessary machinery and specs.

- Limited budget, high cost performance required.

- The customer's workers had no experience in CNC.

Our Solution

- Recommended the 5+1 Bridge Saw, perfect for various materials.

- Demonstrate the actual cutting process through live video.

- Engineer installed machine door-to-door and guided customer first project.

- Establish an after-sales service group for 24/7 support.

Final Results

- Highly satisfied with the machine's quality and performance.

- Valued the thorough after-sales support and plans to recommend our products.

- Daily output: 10 countertops; accuracy ±0.3mm.

- Labor costs are reduced by 30%, with 2 people replacing 4.

- The payback period is shortened from the expected 12 months to 6 months.

Saudi Arabia

Bathroom and Kitchen Furniture Manufacturing

The client has 30+ years of experience in bathroom and tile work and now started a new company to make kitchen and bathroom furniture and related products.

Customer Challenges

- Expanding into kitchen and bathroom furniture.

- Needs suitable CNC, considering bridge cutting saws.

- Price sensitive, comparing 4+1 and 5+1 Bridge Saws.

- Seeks dependable suppliers for new operations.

Our Solution

- Recommended 4+1 Bridge Saw for efficient, budget-friendly work.

- Detailed the benefits of 4+1 over 5+1 models, focusing on cutting capabilities.

- 4+1 is recommended because the customer does not need the bevel function.

- Explained galvanization of critical parts and use of antirust paint for others.

- Arranged customer agent’s visit to verify quality and reliability.

- Offered discount to encourage fast decision, highlighting value.

Final Results

- Customer chose the 4+1 Bridge Cutting Saw, suitable for their needs.

- Smooth process with clear communication.

- Customer confident in product quality and supplier partnership.

What Our Customers Say about Stone CNC Machine

Switzerland

5 Axis Stone Bridge Saw Machine

I had here in China with Blue Elephant with Amber and her colleague together. We had a workshop round about here for one hour.

My impression so far is that your companies are very very professional, highly efficient in the communication, also very kind in terms of hosting. I'm looking forward for the next specialized offers.

BRAZILIAN

3415 Stone CNC Machining Center

We purchased our Blue Elephant stone CNC machine in 2018. It still runs smoothly every day. It’s reliable, precise,

and handles stone engraving and cutting with no issues. A solid investment for our stone workshop.

OMAN

5+1 CNC Bridge Saw

The machine exceeded our expectations. It cuts marble and granite cleanly and consistently.

Setup was easy, and Blue Elephant’s support team was helpful. It's a great fit for our custom stone decoration business.

COLOMBIAN

1515 Stone CNC router

Our Blue Elephant stone CNC machine has improved efficiency in our production line.

It handles complex engraving work on granite and quartz without fail. Maintenance is minimal, and output quality is always high.

About Our Factory

15+ years in business as an industry leader

75000+㎡ High-level Production Base

25+ Dedicated Production Bays

10 technical service centers around the world

30+ locations worldwide

500+ emplovees for service you

8000+ client' Trust and recognition

Exported to 180+ countries and regions

Our Valued Certifications

Blue Elephant CNC machines comply with internationally recognized standards, holding certifications such as CE, ISO9001, BV, SGS, and TUV. Our strict quality control processes and precision engineering ensure high-performance, durable, and reliable solutions that meet the demands of global industries.

25 Ways to Make Money with a Stone CNC Machine

- Custom furniture parts engraving

- Personalized home decoration production

- Commercial signboard production

- Wedding and event decoration props production

- Customized wooden gifts

- Toy and craft carving

- Musical instrument parts production

- Wooden model production

- Customization of pet supplies

- Production of wooden electronic product shells

- Reproduction of calligraphy and painting works

- Production of wooden puzzles

- Customization of brand packaging

- Production of retro-style decorations

- Production of wooden bookshelves and shelves

- Production of teaching aids for educational institutions

- Production of religious supplies

- Production of wooden badges and medals

- Production of outdoor wooden decorations

- Wooden keychain production

- Furniture repair and renovation decoration

- Cooperative mass production

- Provide engraving training services

- Second-hand equipment trading and maintenance services

- Participate in handicraft fairs and exhibitions

Frequently Asked Questions

Yes, Blue Elephant offers flexible customization options. You can adjust the machine size, spindle power, working table type, and control system to suit your specific production needs.

Stone CNC machines are widely used in construction, interior design, monument carving, furniture, and custom decoration. Blue Elephant machines serve clients in these industries by delivering consistent and professional results.

Our machines are designed with durability in mind. Regular cleaning, proper lubrication, and periodic checks are usually enough to keep your Blue Elephant stone CNC machine running smoothly for years.

Yes, Blue Elephant provides professional training and user support. We offer video tutorials, manuals, and one-on-one technical assistance to help you operate your stone CNC machine efficiently.

Our team at Blue Elephant will help assess your material type, workload, and application needs to recommend the best model for your business. We ensure each machine fits your production goals.

Connect With Us

For any inquiries, don’t hesitate to contact us at:

- manager@elephant-cnc.com

- +86 186 6899 1371